Lessons and Activities

They also have kits for sale that include materials for many of the activities, and are constantly pursuing donors to sponsor kits for teachers who may not have the funds to buy it on their own. They have supplied hundreds of donated kits over the past three years.

Demos w/ Liquid Nitrogen

Several demos designed to showcase the unique properties of liquid nitrogen.

Activities include:

- Fun with Liquid Nitrogen

- Superconductivity

- Cold and Hot Processing of Materials

Ceramic processing: slip casting

In this lab, students will gain hands on experience in slip casting a small ceramic object. You can pre-make the molds then have the students slip cast their own part. This can be done in small groups, or individually depending on how many molds are made. If you have access to a high temperature furnace, you could also sinter the part after slip casting.

The building blocks of ceramics

In this lab, various crystal unit cells will be constructed using toothpicks, springs, foam spheres, and twist ties. The students can be broken into groups and will work together to first construct different unit cells with foam spheres connected by tooth picks. They will then construct some of those same unit cells with springs to demonstrate the difference in the strengths. Students will be asked to make predictions about the properties of the resulting crystals based on these unit cell models.

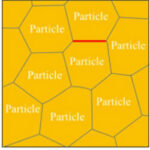

Sintering: grain boundaries, interfaces, and porosity

All materials must be processed in some way to either achieve a particular material property or create a specific shape. There are many different material processing techniques, but one that is fundamental to ceramic materials is sintering. Sintering is a processing technique by which a solid mass of material is formed from the fusion of many smaller pieces, often a powder. This is done primarily through the application of heat but sometimes by adding pressure concurrently.

Demos with liquid nitrogen

Several demos designed to showcase the unique properties of liquid nitrogen.

Activities include:

- Fun with Liquid Nitrogen

- Superconductivity

- Cold and Hot Processing of Materials

Ceramic processing: slip casting

In this lab, students will gain hands on experience in slip casting a small ceramic object. You can pre-make the molds then have the students slip cast their own part. This can be done in small groups, or individually depending on how many molds are made. If you have access to a high temperature furnace, you could also sinter the part after slip casting.

The building blocks of ceramics

In this lab, various crystal unit cells will be constructed using toothpicks, springs, foam spheres, and twist ties. The students can be broken into groups and will work together to first construct different unit cells with foam spheres connected by tooth picks. They will then construct some of those same unit cells with springs to demonstrate the difference in the strengths. Students will be asked to make predictions about the properties of the resulting crystals based on these unit cell models.

Sintering: grain boundaries, interfaces, and porosity

All materials must be processed in some way to either achieve a particular material property or create a specific shape. There are many different material processing techniques, but one that is fundamental to ceramic materials is sintering. Sintering is a processing technique by which a solid mass of material is formed from the fusion of many smaller pieces, often a powder. This is done primarily through the application of heat but sometimes by adding pressure concurrently.

They also have kits for sale that include materials for many of the activities, and are constantly pursuing donors to sponsor kits for teachers who may not have the funds to buy it on their own. They have supplied hundreds of donated kits over the past three years.

Demos w/ Liquid Nitrogen

Several demos designed to showcase the unique properties of liquid nitrogen.

Activities include:

- Fun with Liquid Nitrogen

- Superconductivity

- Cold and Hot Processing of Materials

Ceramic processing: slip casting

In this lab, students will gain hands on experience in slip casting a small ceramic object. You can pre-make the molds then have the students slip cast their own part. This can be done in small groups, or individually depending on how many molds are made. If you have access to a high temperature furnace, you could also sinter the part after slip casting.

The building blocks of ceramics

In this lab, various crystal unit cells will be constructed using toothpicks, springs, foam spheres, and twist ties. The students can be broken into groups and will work together to first construct different unit cells with foam spheres connected by tooth picks. They will then construct some of those same unit cells with springs to demonstrate the difference in the strengths. Students will be asked to make predictions about the properties of the resulting crystals based on these unit cell models.

Sintering: grain boundaries, interfaces, and porosity

All materials must be processed in some way to either achieve a particular material property or create a specific shape. There are many different material processing techniques, but one that is fundamental to ceramic materials is sintering. Sintering is a processing technique by which a solid mass of material is formed from the fusion of many smaller pieces, often a powder. This is done primarily through the application of heat but sometimes by adding pressure concurrently.